| Jumper | Function |

|

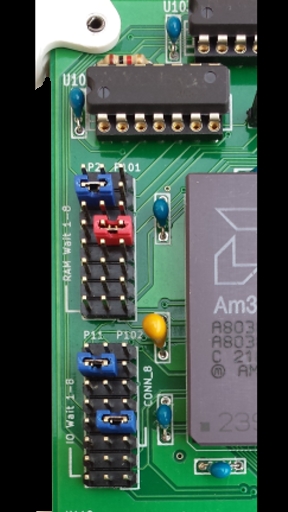

K2 | 1-2,

Pipeline mode always on. (2-3 to set pipeline mode in the CPLD

code) |

|

K101 |

Force the OTT bus access to 16 bit mode 1-2 (normally off i.e. 32 bit

mode) |

|

JP1, JP2, JP3 |

If your S-100 bus is IEEE-696 compatible these jumpers allow extra

ground access to the board. Most S-100 busses don't have this

installed |

|

JP4, JP5, JP6 |

Slave clear, POC & Reset are generated on this board (used only if

board is set as a bus master) |

|

P108 |

pHLDA to S100 bus. For slave configuration 1-2. |

|

JP103 |

Closed, Pullup resistor for pHOLD. |

|

K102 |

Normally 1-2. If 2-3 only 1MG of RAM is visible to the CPU. |

|

JP11 |

Open, pullup resistor for pHLDA |

|

K104 |

1-2 (high). If low (2-3) CPU will immediately go to a

continuous

wait state upon assuming control of the bus. This is used for

hardware debugging. |

|

JP17,19,20 & 21 |

Normally all open unless the board is a bus master. |

|

JP16 |

Normally unused. |

|

K106, K103 |

Jumpers for CPLD Rd/Wr signals to OTT RAM board. Normally 1-2 for

the V10 32/64MB RAM Board |

|

JP101 |

Disable PHI input to CPLD. Used during the initial CPLD programming

cycle where it is open. Normally closed. |

| K3 |

Normally 1-2 for board in Slave mode. 2-3 if bus master. |

|

K107 |

HOLD* signal to S100 bus. For bus slave configuration 2-3. |

|

K5 | CLK

or CLK2 signal to OTT RAM board to clock wait states. Normally 1-2

for the V10 32/64MB RAM Board |

|

P104 |

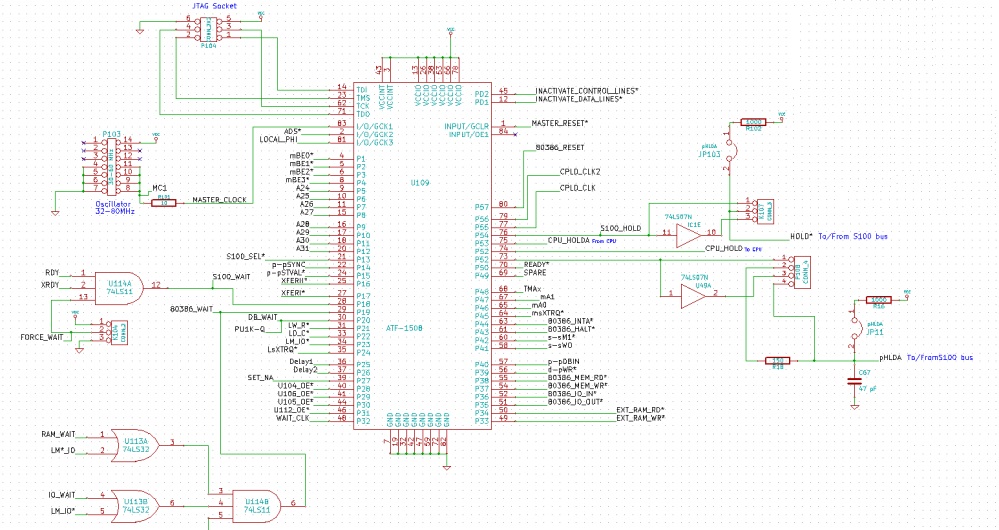

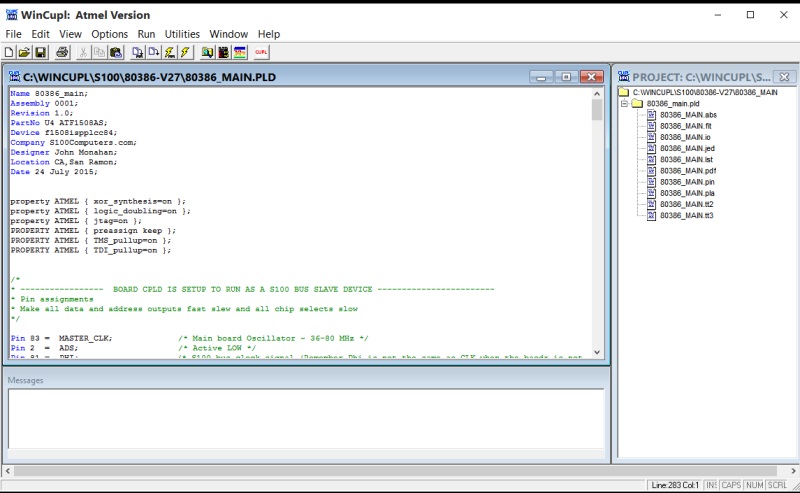

CPLD JTAJ04 programming socket for Rockfield Research 1508

programmer. Pin 1 is bottom left. |

|

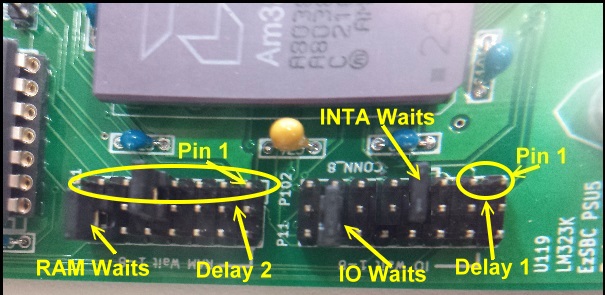

P2,P101,P11,P102 |

Wait state jumpers. See the above text. |

|

RR3, RR2 |

In slave

mode these pins are NOT connected to a pullup resistor network. In

master mode use 1K pullups. |